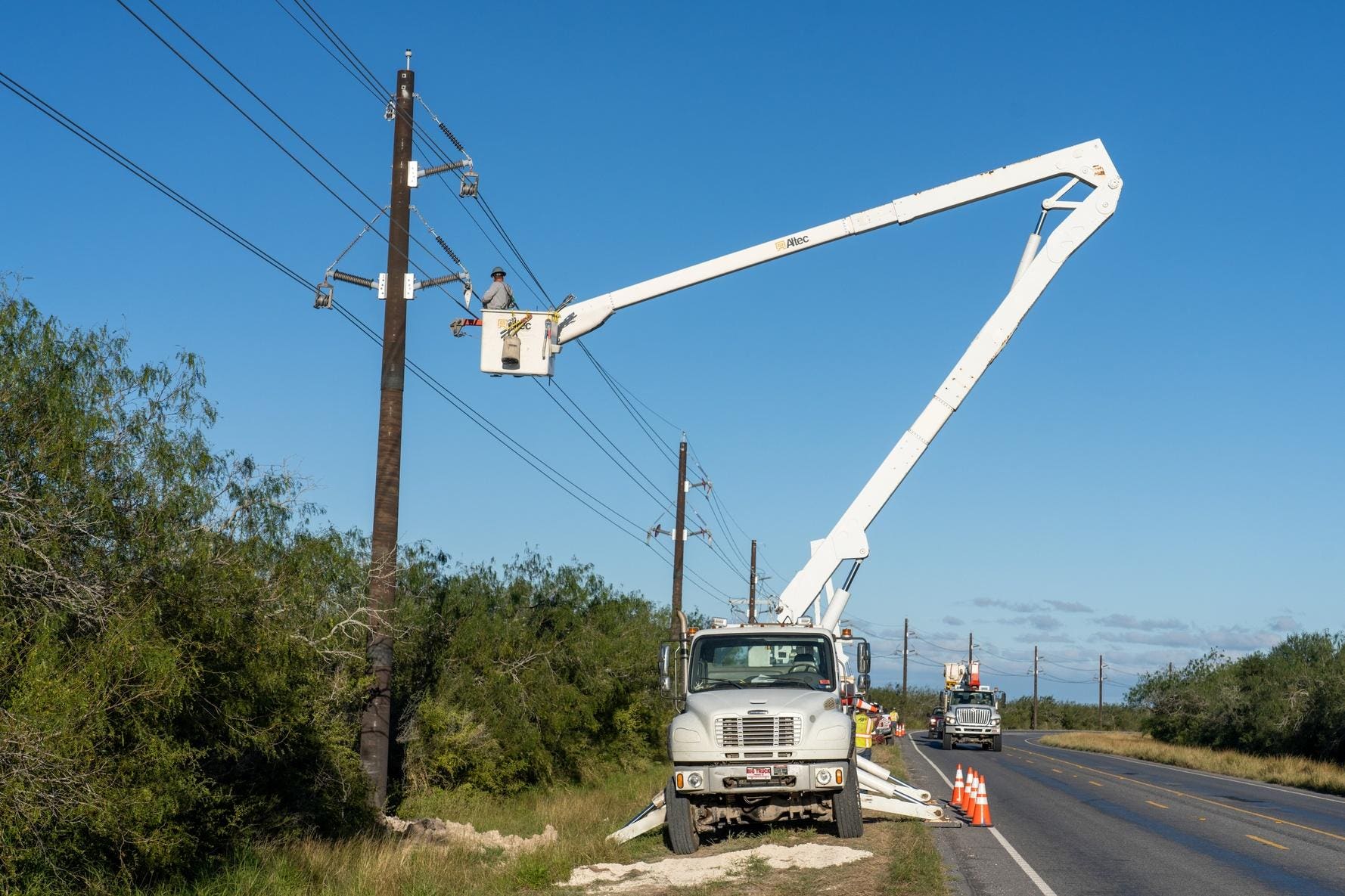

For the average citizen, the vast networks of pipes, wires, and conduits that power modern life are largely invisible. We notice the electric transmission lines only when a crew in a bucket truck is blocking traffic, and we think of the sewage system only when a water main breaks or a basement floods. Yet, the literal foundations of our society—the wooden poles, steel towers, and underground pipelines that transport water, power, and data—are reaching a critical breaking point. In the United States, much of this infrastructure was designed and installed in the mid-20th century, and it is now operating well beyond its intended lifespan.

The scale of the problem is staggering. Roughly 70 percent of the U.S. electric grid was constructed in the 1960s and 1970s. With transmission lines often approaching the end of a 50-to-80-year lifecycle, the risk of catastrophic failure is no longer a theoretical concern; it is a daily reality manifested in wildfires, prolonged blackouts, and systemic inefficiency. Similarly, the nation’s water and wastewater networks are, in many places, over a century old. This aging architecture is being subjected to unprecedented stress from climate change, extreme weather events, and the relentless march of time.

Until recently, the strategy for managing these assets was almost entirely reactive. When something broke, it was fixed. When monitoring did occur, it was manual, requiring skilled technicians to traverse thousands of miles of terrain to inspect assets that, nine times out of ten, were perfectly healthy. This "analog" approach is no longer sustainable. We are witnessing the emergence of a new paradigm: the integration of Physical AI and the Autonomy of Things (AoT™). This technological shift is not merely an incremental improvement; it is a fundamental reimagining of how we maintain the world around us.

The Inefficiency of the Analog Era

The traditional model of infrastructure monitoring is defined by a massive waste of resources. Industry data suggests that over 90 percent of manual monitoring calls result in a "healthy" report. This means that highly skilled labor, specialized equipment, and expensive transportation are being deployed to confirm that nothing is wrong. In an era of acute labor shortages, this is a luxury the industrial sector can no longer afford.

The shortage of skilled "blue collar" labor—linemen, pipefitters, and specialized engineers—is a growing crisis. As the older generation of technicians retires, there are fewer young workers willing to enter fields that require laboring in harsh, often dangerous conditions. When these workers spend the majority of their time on non-productive monitoring tasks, job satisfaction plummets. A skilled professional wants to solve problems and perform complex repairs, not spend eight hours a day driving a truck to look at wooden poles that are still standing. This leads to high attrition rates, further depleting the talent pool.

This labor vacuum has created a fertile ground for the adoption of Physical AI. Unlike Generative AI, which focuses on creating text or images, Physical AI is concerned with the "real" world. It combines sensing, localization, and edge computing to allow machines to perceive, reason about, and interact with physical environments. In the context of infrastructure, this means moving from a world where humans look for problems to a world where the infrastructure monitors itself.

BrightAI: A New Operating System for Reality

At the center of this transformation is BrightAI, a company that has positioned itself as a pioneer in "Stateful" operations. Founded in 2019 and led by Alex Hawkinson—frequently cited as the "Father of IoT" for his previous success with the SmartThings platform—BrightAI is attempting to do for industrial infrastructure what the smartphone did for personal communication.

Hawkinson’s vision is centered on "observability." To manage a problem as vast as the U.S. power grid or water system, you must first be able to see it in real-time. BrightAI’s "Stateful" platform acts as a real-time operating system for the physical world. It fuses data from a variety of multimodal sensors—including LiDAR, thermal imaging, acoustic sensors, and high-resolution cameras—to provide operators with a "digital twin" of their physical assets.

The company’s growth reflects the desperate need for these solutions. With over $78 million in total funding and $100 million in revenue to date, BrightAI has deployed over 250,000 AI endpoints across 50,000 locations. These endpoints aren’t just passive sensors; they are intelligent nodes capable of making decisions at the "edge." By processing data locally rather than sending everything to the cloud, these systems can identify imminent failures—such as a transformer overheating or a pipe beginning to hairline crack—and alert crews instantly.

Case Study: Fortifying the Electrical Grid with Osmose

One of the most compelling applications of this technology can be found in the work of Osmose Utilities Inc. Founded nearly a century ago, Osmose has spent decades specializing in the preservation of the grid’s most basic component: the wooden pole. While it may seem primitive in an age of fiber optics and satellites, the wooden pole remains the backbone of the "last mile" of electricity delivery.

A mid-size utility might manage upwards of one million poles, each representing an installation cost of roughly $15,000. These poles are under constant assault from wood decay, insect infestations, and soil erosion. Traditionally, inspecting these poles required technicians to manually dig around the base or climb them to check for structural integrity.

By partnering with BrightAI, Osmose has transitioned to a "Resiliency as a Service" (RaaS) model. Using drones equipped with LiDAR and thermal imaging, they can conduct aerial surveillance of transmission structures at a pace that was previously impossible. These drones can fly into "energized" environments—like high-voltage vaults or manholes—to assess the condition of cables and towers without putting human lives at risk. The AI-driven analysis of this data allows Osmose to predict which poles are likely to fail years before they actually do, enabling targeted reinforcement that can extend the life of a pole by 40 years or more. This data-driven approach allows utilities to execute repairs five times faster and at a fraction of the cost of traditional replacement.

Case Study: The Invisible Crisis of Water Infrastructure

The situation below our feet is even more dire. The United States loses an estimated 2.1 trillion gallons of treated water every year due to leaking pipes and aging mains. Azuria, a leader in water solutions, is tackling this problem through a combination of specialized robotics and Physical AI.

Azuria’s core innovation is the Cured-In-Place Pipe (CIPP) process, a "trenchless" technology that allows for the repair of underground pipelines without the need for massive excavation. In this process, a resin-saturated liner is inserted into the existing pipe, expanded, and then cured using heat or UV light, essentially creating a new, durable pipe inside the old one.

However, the challenge has always been knowing where to apply this fix. Underground environments are notoriously difficult for sensors; they are dark, wet, and often filled with debris. By integrating BrightAI’s sensor suites and edge computing into their pipeline robots, Azuria has given these machines a "brain." These robots can now autonomously navigate through sewage and stormwater lines, using thermal cameras and LiDAR to detect cracks and structural anomalies that are invisible to the human eye.

As Rob Tullman, CEO of Azuria, notes, this technology allows for informed decision-making right on the job site. The robot identifies the scope of work, directs the human crew to the exact point of failure, and in the near future, will be capable of performing the repairs autonomously. This not only improves the quality of the projects but significantly enhances staff retention by removing the drudgery and guesswork from the job.

The Future of Blue Collar Autonomy

The convergence of Physical AI and critical infrastructure monitoring is part of a broader trend known as "blue collar autonomy." While much of the public’s attention has been focused on autonomous passenger cars, the real revolution is happening in "unadvertised" sectors like mining, agriculture, logistics, and waste management.

In these industries, autonomy is not about replacing humans; it is about augmenting them. By automating the dangerous, repetitive, and inefficient aspects of infrastructure maintenance, we allow human talent to focus on high-value problem-solving. This shift is essential for the economic health of modern nations. Without a resilient grid and a functioning water system, the high-tech economy of the 21st century—from data centers to semiconductor manufacturing—cannot exist.

Looking forward, the trend is toward even greater "in-situ" intelligence. We are moving toward a world where the infrastructure is "self-aware." Imagine a power pole that can detect its own structural fatigue after a storm and automatically dispatch a repair drone, or a water system that can reroute flow and seal its own leaks using autonomous robotic inserts.

The integration of Physical AI into our aging infrastructure is a wakeup call for the industrial world. It represents a shift from reactive crisis management to proactive stewardship. As we face the dual challenges of a shrinking workforce and a decaying physical foundation, the "Intelligence of Things" offers a path toward a more resilient, sustainable, and efficient future. The invisible networks that support our lives are finally being given the eyes and brains they need to survive the century ahead.