The foundational material of modern civilization, concrete, is on the precipice of a radical transformation, moving beyond its traditional role as a passive load-bearing composite to become an active, integrated component of the global energy infrastructure. Researchers at the Massachusetts Institute of Technology (MIT) have substantially advanced the capabilities of an innovative variant known as electron-conducting carbon concrete, or $textec^3$, pushing the material closer to viability as a massive, decentralized energy storage medium. This breakthrough is not merely incremental; it represents an order-of-magnitude increase in energy storage capacity, suggesting that the structures we inhabit and rely upon—from basement walls to sprawling bridges—could soon function as giant, resilient supercapacitors.

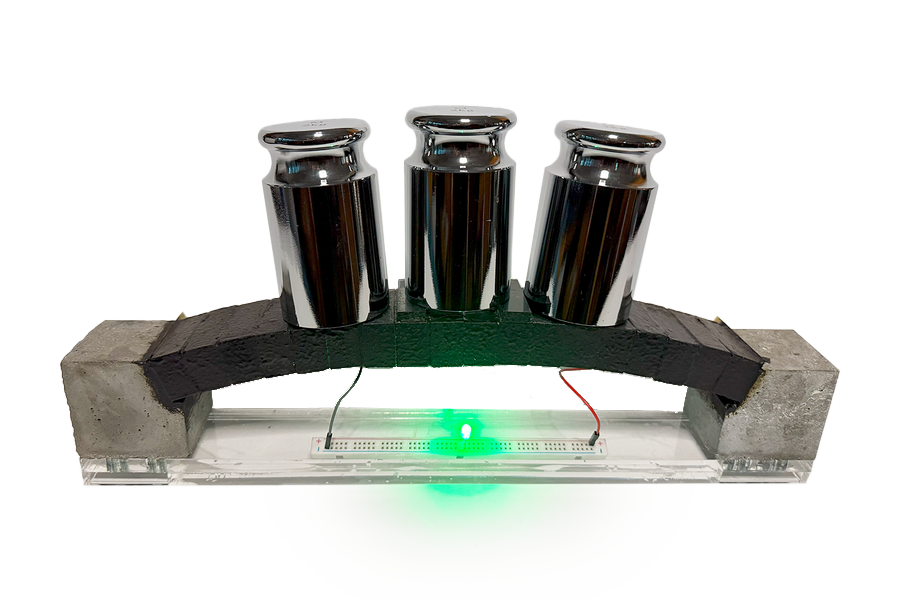

The concept hinges on integrating electrical storage directly into the matrix of the building material itself. $textec^3$ achieves this by modifying the standard concrete recipe, incorporating ultra-fine carbon black particles and specific electrolytes into the cement-water mixture. This creates a highly dense, conductive nanonetwork throughout the material’s porous microstructure. When cured, the concrete essentially becomes a porous electrode. By introducing an electrolyte—a medium that facilitates ion movement—the entire structural element functions as an electrochemical capacitor, capable of rapidly absorbing and discharging electrical energy.

This recent leap in performance, documented by the MIT Electron-Conducting Carbon-Cement-Based Materials Hub, overcomes major limitations that had previously confined $textec^3$ to the laboratory: low voltage and insufficient storage density. The team’s focused research, leveraging advanced high-resolution 3D imaging techniques, provided unprecedented insight into the complex interaction dynamics between the conductive carbon network (the electrode) and the ionic solution (the electrolyte). Understanding the geometry and connectivity of this internal nanonetwork allowed the scientists to optimize the material’s formulation, fundamentally enhancing ion diffusion kinetics and charge separation efficiency.

The practical implications of this optimization are profound. Estimates suggest that a volume of approximately five cubic meters of this improved concrete—roughly equivalent to the typical footprint of a residential basement wall—could store enough energy to satisfy the entire daily electrical consumption of an average American home. This moves structural storage from a theoretical curiosity into the realm of realistic, grid-scale application.

The Imperative for Massive Volume Storage

To fully appreciate the significance of structural energy storage, it must be placed within the context of the global transition to renewable energy. The increasing penetration of intermittent sources, namely solar and wind power, has exposed a critical vulnerability in existing electrical grids: the mismatch between energy generation peaks and consumption demands. This intermittency necessitates vast, flexible energy storage solutions, often referred to as Long-Duration Storage (LDS), to stabilize the grid and ensure reliable power delivery when the sun is not shining or the wind is not blowing.

Current storage solutions, predominantly based on lithium-ion (Li-ion) chemistry, face inherent constraints related to cost, material sourcing (especially cobalt and nickel), end-of-life recycling challenges, and, critically, physical footprint and thermal runaway risks. While Li-ion excels in high energy density for mobile applications (electric vehicles), its suitability for massive, static, long-term infrastructure storage is often questioned, especially in urban environments where land is expensive and safety regulations are strict.

$textec^3$ offers a competing paradigm: Massive Volume Storage (MVS). While its energy density per kilogram does not rival Li-ion, the material’s competitive advantage lies in its ubiquitous deployment potential. Concrete is the most consumed material on Earth after water, produced at rates exceeding 4 billion tons annually. If even a fraction of new concrete infrastructure could double as storage, the total capacity available to the grid would dwarf existing battery installations. The structure itself becomes the energy reservoir, eliminating the need for dedicated land, expensive housing units, and separate foundation construction required by conventional Battery Energy Storage Systems (BESS).

Technical Analysis: Supercapacitor Dynamics and Materials Science

The functionality of $textec^3$ is rooted in the principles of a supercapacitor, or electrochemical double-layer capacitor (EDLC), rather than the far more complex chemical reactions governing traditional batteries. In a supercapacitor, energy is stored via the physical separation of charge (ions) at the interface between the conductive electrode material (the carbon network) and the electrolyte. This mechanism allows for extremely fast charging and discharging cycles and offers exceptional cycle life, often measured in the hundreds of thousands of cycles, significantly exceeding the typical lifespan of chemical batteries.

The research team’s success hinged on optimizing two core components: the internal surface area and the electrolyte composition. The use of ultra-fine carbon black maximizes the accessible surface area within the concrete’s pores—the larger the effective surface area, the greater the number of ions that can accumulate, thus increasing capacitance.

The investigation into alternative electrolytes yielded particularly groundbreaking results. By experimenting with various salt concentrations, the team confirmed that inexpensive, readily available saline solutions, including treated seawater, function effectively within the $textec^3$ matrix. As noted by researchers, this finding opens the door to critical coastal and marine applications. Imagine the support structures for offshore wind farms—massive concrete monopiles or floating platforms—not only anchoring the turbines but also storing the generated electricity locally before transmission. This dual function drastically simplifies logistics, reduces material costs, and improves system resilience in demanding maritime environments. Furthermore, utilizing abundant materials like salt and carbon minimizes the environmental and geopolitical concerns associated with mining rare battery metals.

Industry Implications: A Paradigm Shift in Civil Engineering

The successful implementation of structural energy storage will necessitate a fundamental reassessment of civil engineering practices. Infrastructure is typically designed for strength, durability, and resistance to environmental factors. The introduction of an electrical function requires engineers to master a new set of criteria related to conductivity, insulation, and electrochemical stability over decades.

Smart Infrastructure and Resilience: $textec^3$ enables the creation of truly smart infrastructure. Bridges could store solar energy generated by integrated photovoltaic panels on their surfaces, powering structural health monitoring sensors, illumination systems, and de-icing mechanisms, all without relying on external grid connections. Highways built with $textec^3$ could potentially store energy harvested from regenerative braking systems or inductive charging coils, enabling decentralized charging networks for electric vehicles embedded directly into the pavement.

Decentralized Power Generation: The distributed nature of $textec^3$ offers an unparalleled level of grid resilience. In the event of catastrophic grid failure, individual buildings, tunnels, or community microgrids constructed with this material could maintain critical functions (emergency lighting, communication systems) for extended periods. This distributed architecture contrasts sharply with centralized storage facilities, which remain vulnerable to single points of failure.

Economic Modeling and Lifecycle Cost: While the initial cost of $textec^3$ (due to the inclusion of specialized carbon materials and precise mixing protocols) may exceed that of traditional Portland cement, the long-term economic case is compelling. The analysis shifts from comparing material costs to comparing system costs. When a structural element serves both its primary function (load-bearing) and its secondary function (energy storage), the cost of the dedicated storage system is effectively zeroed out. Moreover, the inherent longevity of concrete—often engineered for 50 to 100 years—means the storage system’s lifespan aligns with the structure’s, providing a massive advantage over Li-ion batteries, which typically require replacement every 10 to 15 years. This durability translates directly into superior lifecycle cost efficiency.

Challenges on the Path to Commercialization

Despite the immense promise, several complex engineering and regulatory hurdles must be cleared before $textec^3$ moves from pilot projects to global deployment.

1. Structural Integrity and Electrochemical Degradation: The primary challenge lies in ensuring that the continuous cycling of charge and discharge does not compromise the structural integrity of the concrete over decades. Electrochemical processes inherently involve the movement of ions, which can lead to localized stresses, micro-cracking, or the leaching of essential components over time. Researchers must rigorously test the material’s long-term performance under simultaneous mechanical stress (e.g., traffic load on a bridge) and electrochemical cycling to ensure it retains its compressive strength and durability characteristics required by international building codes.

2. Manufacturing Scale and Quality Control: Achieving the precise, homogeneous distribution of ultra-fine carbon black particles and the controlled infusion of electrolytes across massive volumes of concrete presents a significant manufacturing challenge. Standard concrete mixing practices are often coarse and variable. Scaling up $textec^3$ production requires highly sophisticated quality control systems to ensure the nanonetwork is consistently formed across batches, guaranteeing predictable electrical performance and structural uniformity.

3. Voltage and Power Output Limitations: As a supercapacitor operating with a water-based electrolyte, $textec^3$ inherently operates at relatively low voltages (typically below 1 volt per cell). While low voltage is inherently safer, it requires complex electrical engineering solutions—such as stacking numerous concrete cells in series—to achieve the higher voltages necessary to interface effectively with standard AC grid infrastructure or power modern appliances. The engineering focus must shift toward optimizing cell geometry and interconnection methodologies to maximize voltage output and energy harvesting efficiency.

4. Regulatory and Certification Frameworks: Currently, building codes and material certifications are entirely separate from electrical standards. A new category of material certification must be established for structural energy storage composites that satisfy both civil engineering requirements (ASTM/ISO for concrete strength and durability) and electrical engineering standards (UL/IEC for safety, capacitance, and cycling stability). This regulatory harmonization will be a critical, non-trivial step toward market acceptance.

The Integrated Future of Architecture and Power

The developments in electron-conducting carbon concrete signify a fundamental shift in how we conceptualize the built environment. Structures are no longer static shields; they are becoming dynamic, functional components of the technological landscape. This convergence of materials science, civil engineering, and electrochemistry paves the way for a future where energy resilience is baked into the very foundation of our infrastructure.

The ultimate vision is one of energy autonomy for the built environment. As research progresses, structural materials like $textec^3$ will likely integrate other functions—such as thermal regulation, self-healing capabilities, and integrated data transmission—creating truly multi-functional, adaptive, and sustainable infrastructure. By harnessing the massive volume potential of concrete and leveraging the reliability of supercapacitor technology, researchers are laying the groundwork for a decentralized, robust, and environmentally responsible power grid, cemented, quite literally, into the fabric of our world.